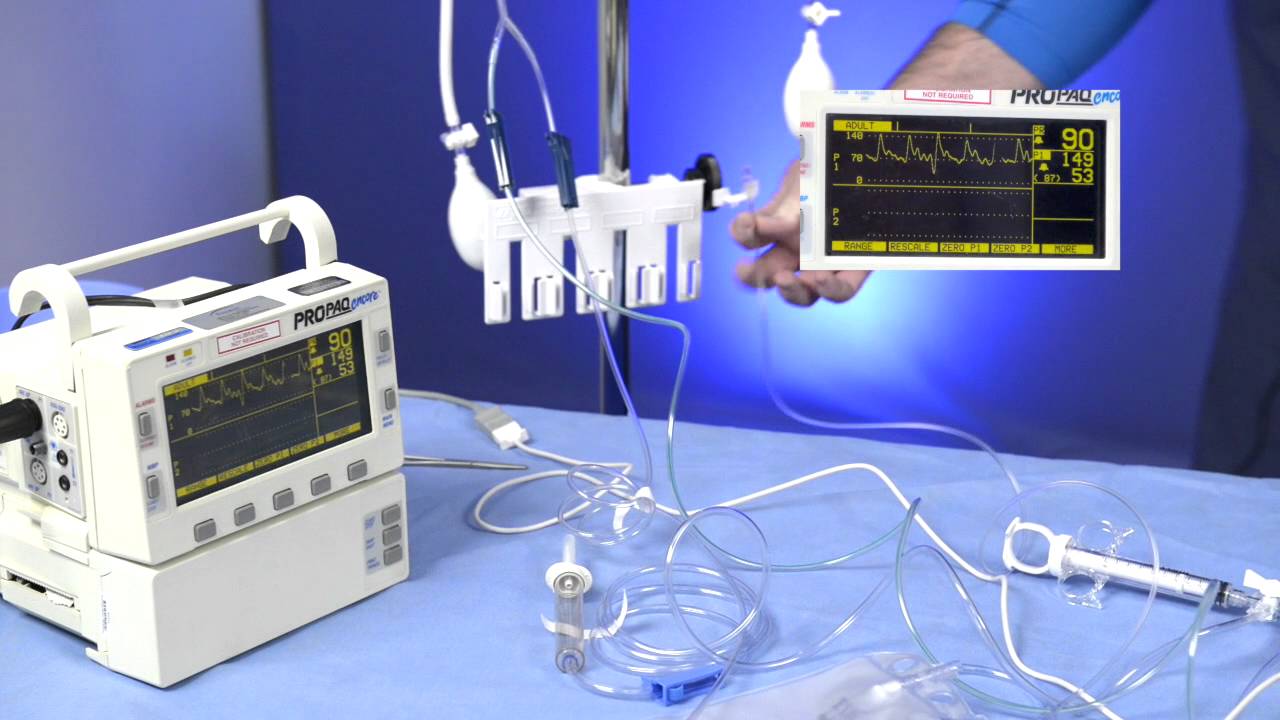

Transducer Calibration

As an ISO 17025 certified company, GL Technologies specializes in equipment calibration and certification services for biopharmaceutical clients throughout California. Transducers play an important role in capturing and converting physical quantites into electrical signals, making these instruments indispensable for monitoring and controlling various processes. Transducers need to be calibrated regularly to provide accurate measurements. Our team has extensive knowledge in biopharmaceutical equipment calibration for both research and manufacturing processes, keeping our clients equipment accurate and maintaing compliance with federal regulations.

To speak with the experts about your transducer calibration needs, please fill out our online form or give us a call!

How is a Transducer Used in a Laboratory?

In a laboratory, a transducer is a device that converts 1 form of energy or physical quantity into another. Transducers have an important role in scientific research and experimentation by enabling measurement, detection, or conversion of various parameters like temperature, pressure, light, sound, or electrical signals. Transducers can be found in a wide range of lab equipment, including sensors, probes, and instruments used for data acquisition and analysis. They facilitate the transfer of information between the physical world and the digital realm, giving scientists the ability to gather accurate measurements and study the behavior of different phenomenon within the controlled environment of a laboratory.

Why Transducer Calibration Matters

Here are some reasons why transducer calibration is crucial:

Accuracy

Transducers, no matter if they are used in measuring devices, sensors, or instruments, are designed to convert physical quantities into electrical signals, but over the course of time and with usage, their performance can drift which can lead to inaccuracies in measurements. Calibration compares the output of a transducer against a known standard to verify that the readings remain precise and reliable. With transducer calibration, any deviations can be identified and corrected to maintain the needed level accuracy.

Compliance with Regulations

Compliance with calibration standards not only guarantees the quality of data collected but also verifies the safety of individuals and the integrity of processes. Properly calibrated transducers improve product quality, allowing for accurate diagnosis and supporting efficient operations. With transducer calibration, organizations can maintain compliance and minimize risks.

Process Optimization

The calibration process eliminates inherent errors, drift, and deviations which results in precisemeasurements. With regular calibration, businesses can maintain consistent process control and improve product quality. Accurate data obtained through calibration allow for informed decision-making, a reduction in downtime, and provides for proactive maintenance. This leads to optimized processes and cost savings.

Key Considerations for Transducer Calibration

The following considerations should be taken into account:

Calibration Frequency

The frequency for which calibration should be performed depends on a few factors including the specific application, environmental conditions, and the manufacturer's recomendation. High-precision applications for those that require critical measurements may need more frequent calibration intervals. Laboratory applications that are less demanding may allow for longer intervals. Environmental factors such as temperature and humidity can impact the performance of transducers, warranting frequent calibration in harsh conditions.

Traceability and Standards

Traceability verifies that the calibration process can be linked back to industry reference standards, establishing a reliable and verifiable measurement chain. This is important for maintaining accuracy and credibility in various biopharmaceutical industries such as manufacturing and research. Standards also play an important role in transducer calibration by providing a set of guidelines and procedures to keep track of consistency and comparability of measurements. By adhering to recognized standards, it improves the reliability of calibration results and facilitates compatibility of transducers across different systems. A comprehensive calibration process needs to prioritize traceability to reference standards.

Documentation

Biopharmaceutical companies need to carefully document the calibration process, including all necessary information such as equipment that was used, calibration standards employed, and any environmental conditions that may impact measurements. It's also recommended to document any deviations found for future troubleshooting, and document the technician's name and company along with the date/s of calibration.

Environmental Conditions

Environmental factors including temperature, humidity, and pressure can significantly impact the accuracy and reliability of measurements. It's important to control and monitor these conditions throughout the calibration process. Temperature variations can cause thermal expansion or contraction, which affects the transducer's dimensions and performance. High humidity levels can lead to condensation and corrosion, potentially altering the transducer's electrical properties. Electromagnetic interference from nearby electronics can introduce noise and interfere with the transmitter's signals. By carefully managing these environmental conditions, accurate transducer calibration can be achieved.

Why GL-Tec?

The GL Technologies team has the experience and equipment to calibrate all types of display equipment accurately. We understand the importance of accurate measurements in your specific industry, and we're committed to providing you with reliable, traceable calibration services.

Our calibration services are ISO 17025 accredited, and we follow strict quality control procedures. Your equipment is calibrated to the highest standards. We also provide fast turnaround times, so you can get back to work with minimal downtime.

To speak with the experts about your transducer calibration needs, please fill out our online form or give us a call!

To request a quote from GL-Tec, please fill out our online form and we will get back to you promptly.

CLICK HERE TO BEGIN