Los Angeles Dionex HPLC Calibration Services

As the trusted team of experts in the Los Angeles biopharmaceutical and related industries, the team at GL Technologies has the experience needed to provide calibration services to Dionex equipment. High-Performance Liquid Chromatography (HPLC) is a powerful analytical technique that is widely used in scientific research, pharmaceuticals, and industry. HPLC systems, such as those offered by Dionex, rely on precise calibration to ensure accurate and reliable results. GL Tec understands the importance of Los Angeles Dionex HPLC calibration and how it can impact your analysis.

To speak with the experts about your Dionex HPLC Calibration needs, please fill out our online form or give us a call!

Why is Dionex HPLC Calibration Important?

Accurate and reliable results are critical when performing HPLC analysis. Any deviation from accurate results can lead to incorrect conclusions, leading to significant consequences in research, manufacturing, and patient care. Calibration is essential to ensure that the instrument provides the correct results, time and time again.

Calibration also plays a role in the performance of the HPLC system. A poorly calibrated system can lead to poor separation, reduced sensitivity, and decreased accuracy. Calibration can help identify any issues with the system and help optimize its performance.

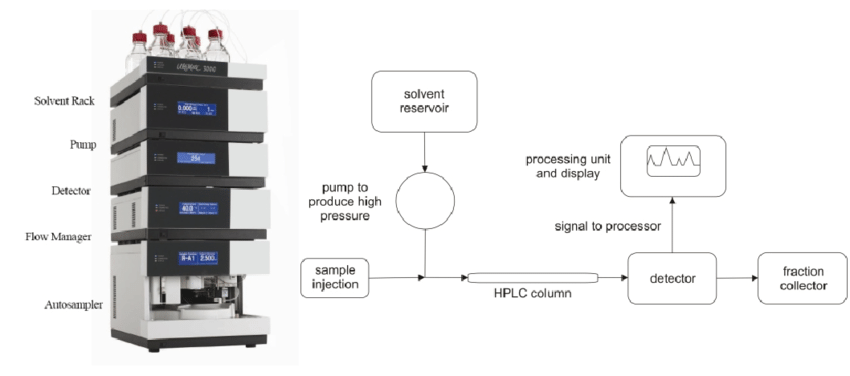

How is Dionex HPLC Calibration Performed?

Los Angeles Dionex HPLC calibration typically involves a series of tests to ensure that the instrument meets the manufacturer's specifications. Calibration usually involves the use of certified reference materials (CRMs) to verify the accuracy of the instrument. CRMs are substances with known properties that can be used to verify the performance of the instrument.

Calibration also involves making adjustments to the instrument if necessary. These adjustments may involve adjusting the flow rate, pressure, or temperature of the system. After calibration, the instrument is retested to ensure that it meets the required specifications.

The Benefits of Dionex HPLC Calibration

Accuracy in Analysis

Calibrating a Dionex HPLC system is vital in providing accuracy in analytical results. Calibration not only guarantees the reliability of data but also improves the overall efficiency of the HPLC system. By tuning parameters including flow rates, detector sensitivity, and retention times, a properly calibrated Dionex HPLC system allows for the accurate quantification of compounds in complex samples.

Consistency

With regular calibration, the HPLC system is fine-tuned to deliver reliable and reproducible data, making sure that results obtained from different instruments remain consistent over time. This consistency is vital in analytical chemistry as it allows scientists to confidently compare and analyze samples, track changes, and make informed decisions in research.

Compliance

Maintaining calibration protocols is vital for regulatory compliance, particularly in the biopharma and pharmaceutical industries where precision and accuracy are critical. Compliance with calibration protocols can help organizations avoid costly deviations and fines while improving the credibility of their analytical processes.

Best Practices for Dionex HPLC Calibration

Scheduled Calibration

Scheduled calibration is a best practice that validates the instrument’s performance remains consistent over time. To start, it’s important to establish a regular calibration schedule, typically ranging from daily to monthly depending on the usage frequency and criticality of analysis. During the calibration, attention will be paid to setting the correct flow rate, detector wavelength, and injection volume, as well as verifying the system’s pressure and baseline stability. It’s important to use certified standards and reference materials to calibrate and validate the system.

Use Standard Solutions

For precision and reliability in your results, it’s imperative to regularly calibrate HPLC systems using certified reference materials or prepared standard solutions of a known concentration. These standards should closely mirror the analytes of interest, and calibration curves need to cover the desired concentration range.

Documentation

All calibration steps need to be documented, detailing the calibration standards used, measurement results, date, and the responsible technician or company. This documentation should be stored for future references and audits. Regularly review and update calibration procedures, keeping them aligned with industry standards and regulations, thus maintaining the accuracy and traceability of your analytical data.

Training

It’s important to stick to a systematic training program for technicians, emphasizing a thorough understanding of the instrument’s components and software, as well as a comprehensive grasp of the calibration process. Documentation and record-keeping should be kept allowing for traceability and auditability.

Instrument Performance Verification

Beyond regular calibration, conduct instrument performance verification tests to ensure the HPLC system's overall functionality is up to par.

GL Technologies Capabilities

As a full-service company specializing in equipment calibration, repair, and certification services for biopharmaceutical, pharmaceutical, and medical device industries. Our team has extensive experience working with sPRT calibrations along with CMMS software, HPLC OQ validation, and fume hood certifications. Companies of all sizes rely on our team to implement, maintain, and keep their research and manufacturing processes compliant with regulatory standards. Other specialties include building maintenance systems, and mass spectrometry calibrations.

To speak with the experts about your Dionex HPLC Calibration needs, please fill out our online form or give us a call!

To request a quote from GL-Tec, please fill out our online form and we will get back to you promptly.

CLICK HERE TO BEGIN